Have there been advantages to domestic lighting manufacture in this past year where COVID-19 has disrupted supply chains and the ability to work as normal all while increasing demand? Companies that produce lighting in North America think so, despite having to work around early shutdowns, regulations and materials procurement issues, along with an uptick in orders. According to Max Cohen, Director of Hospitality Lighting for Meyda Lighting, in Yorkville, NY, and Nancy Shott, Vice President of Marketing at Hammerton/ Hammerton Studio, based in Salt Lake City, planning has been instrumental to staying on track and servicing customers as expediently as possible despite some of the challenges.

“Being a domestic manufacturer with 100 percent of operations under one roof gives us greater control over our people and processes, so we can be nimble and adapt quickly to change,” Shott says. “Much of our production involves custom work, which can be enormously complex. Internally, it requires a level of operational excellence that allows us to identify and resolve problems even before they come up. Externally, it requires more intimate relationships with customers and seamless communication between all stakeholders — designer, architect, homeowner, builder, electrician, etc. All of that is very hard to accomplish under a more traditional lighting manufacturer model where operations are distributed across various locations, often on either side of the Pacific.”

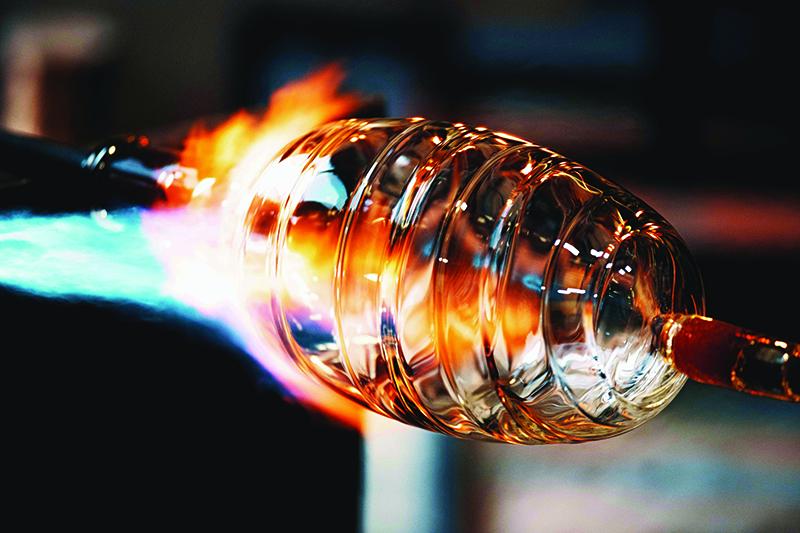

At Meyda, that ability to coordinate within the same space has also been important to the company's continued ability to produce efficiently, as much of their domestic production has been focused on custom capabilities as well. One of the ways the company is expanding its ability to deliver quickly is by bringing more processes in house than ever before. “While we’ve been doing this for the past 25 years, the uptick in demand has made it important for us to be more self-reliant, not just from the perspective of different countries, but within our own country as well,” Cohen notes. “So we are going bigger. We are expanding a lot of our manufacturing capabilities and buying new equipment, and doing more processes in house than we ever have before. We are completely vertical at this point.”

Meyda has a 180,000-square-foot facility that incorporates manufacturing and warehousing, as the company has offered a combination of domestic and imported lighting options. In this past year, however, the focus has shifted, and Meyda is utilizing more of its space for manufacturing. “It’s been easy to grow into different areas of our facility because we have the space,” Cohen says.

Another advantage of that space has been the ability to order materials and components early and in larger quantities. “We have a very large warehouse,” Cohen comments. “We import the components we need at very high volume. We don’t run out of those.”

“Our supply chain is not heavily reliant on cargo ships,” says Hammerton’s Shott. “Most materials we source internationally are smaller components that can be cost effectively shipped on an airplane. We source critical materials from multiple vendors, and we manage those relationships as strategic partners.”

More Demand Means More Jobs

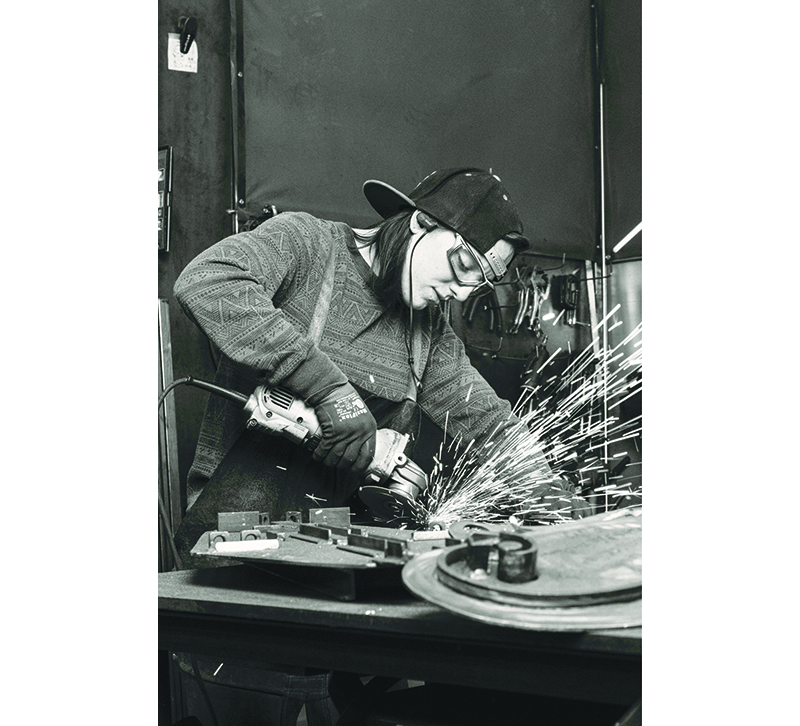

Even with careful materials and production management, increased product demand has meant more need for staffing to get the jobs done. Again, with domestic production, while there are still challenges, being hands-on with employee training and workflow allows these companies to have more leverage where needed.

Meyda’s lead times were down to about 12 weeks at presstime, says Cohen, and it continues to get better. The longer-than-usual production turnaround is partly due to earlier shutdowns and the aforementioned higher demand. However, the company has the ability to create a flexible work environment through training. “We have a training program, and regardless of what [an employee] does, they understand how everything works. Even the engineers are trained on different processes,” says Cohen. “We’re also expanding programs with local labor sources, trade schools and high school certificate programs. We’re doing everything we can so we are on the radar for anyone who wants a career in lighting production.”

Meyda’s efforts are paying off as the company sees its production lead times improving with each passing week. Constant communication with customers and the ability to juggle projects that might have more priority has also helped keep things running smoothly. Even with some delays, Meyda can have more accurate communications with its customers because it is located in the United States. Even if lead times are slightly longer right now, they are reliable.

At Hammerton, while lead times are still longer than normal as well, bringing them back in line is the company’s top priority and they are getting shorter every week. In addition, the company is able to manage customer expectations through consistent communication. “We talk to our customers every single day. It’s difficult to make good decisions on order management without understanding each customer’s requirements,” Shott says.

She adds, “You have to manage your production strategically.” At Hammerton, that involves training for flexibility. “We really try to maintain a flexible staff with a broad skill set so we can proactively address bottlenecks and pain points within the production process. We are vastly more efficient today than we were even a few years ago, and maintaining a focus on continuous improvement has been key to that.”

The bottom line, say these lighting manufacturers, is building relationships with customers, particularly with so much custom production. That’s also easier to do when the company is domestic. “Our customers can tour our facility and sit down with our design team,” Shott says.

As vaccines roll out and COVID and supply chain issues abate, domestic lighting manufacturers expect to see continued increasing demand for what they can provide. “I believe Made in America is going to grow, it’s not going to shrink,” says Cohen. “We have the ability to control lead times are a bit better, the ability to make sure the quality is as promised. It all falls under the same umbrella, and it’s about that control. We’re still here, and we’ll be here for a long time.”