The greatest example of what it means to be American may be hanging in foyers, dining rooms and lighting showrooms across the country in the form of U.S.-made lighting fixtures. Each part — from the metal and glass to the components and wiring — comes from somewhere, sometimes from another town, state, across the border or even an ocean.

As the makeup of the United States is often described as a melting pot, so too are the lighting fixtures created here by American hands.

Whether the end customer recognizes it or not, lighting fixtures made in the U.S. represent far more than just domestic manufacturing. Their parts may come from suppliers all over the world, but it’s the domestic craftsmen and women who take all the parts to create something beautiful, wholly unique and 100 percent American.

Custom Designs

For those watching the evolution of furniture manufacturing in the U.S., custom options, giving the customers choices for size, finish and material, provide domestic makers with a competitive edge. Custom products give clients that one-of-a-kind look over mass-produced pieces. Domestic manufacturers can offer shorter lead times as well, and they have greater control over the designs and quality of products. In lighting, U.S.-based manufacturers see similar benefits.

“The good news is that you’re never bored when you’re manufacturing here,” Jeanne-Marie Gand, Vice President of Marketing at Hubbardton Forge, jokes. “It’s never a line.”

Located in Castleton, VT, Hubbardton Forge and its sister brands, Vermont Modern, Synchronicity by Hubbardton Forge and HF Reflections, prides itself on being “one of the country’s oldest and largest continuously operating commercial forges.” With about 230 people employed, Hubbardton Forge uses a made-to-order production method, which keeps it competitive. Only raw materials need to be kept in stock, and nothing is made until a purchase order comes in. For employees, that means every day is a little different, and for clients, lighting fixtures can be adjusted, if needed, to fit the space just right.

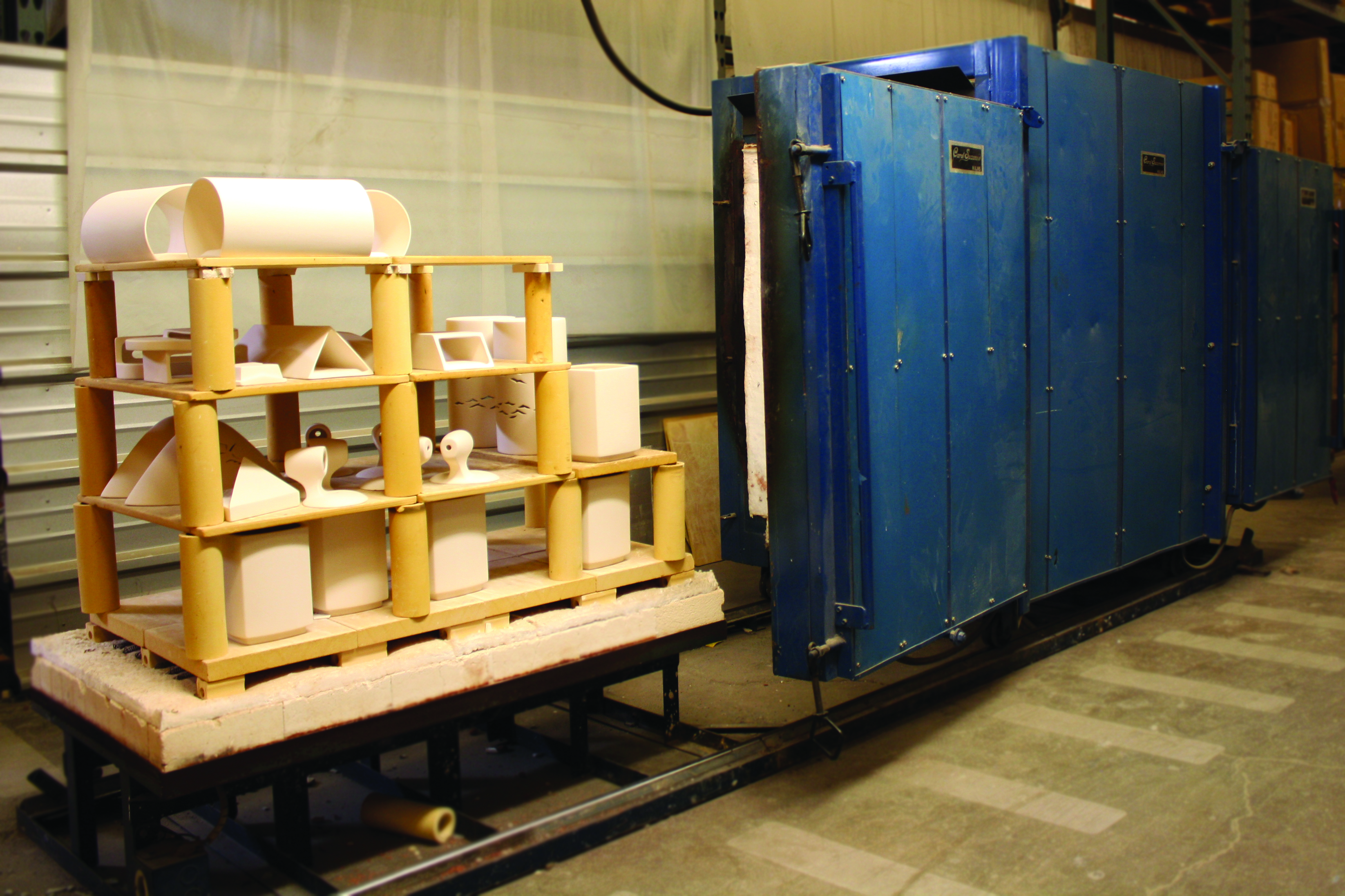

That mindset is picking up across the country. In Los Angeles, Justice Design Group has seen an uptick in interest in its Form+Finish+Function ceramic program. The program, manufactured stateside, lets customers pick just about every aspect of their ceramic fixtures, which is a big deal for retail customers and especially commercial customers. Justice’s President Brandon Levin says customers can choose from a handful of styles, finishes, textures, shapes and even lamping options when designing their lighting.

“More people are asking about [custom options],” he adds. “We are making marketing efforts in that regard.”

Justice represents a hybrid domestic manufacturing model. About 25 percent of its business comes from the Form+Finish+Function program — all manufactured in the U.S. — and about 60 to 70 percent of its products are at least assembled in the U.S. The rest is imported. As interest in American manufacturing grows, Levin hopes the company will do more domestic manufacturing, but even if the U.S.’s ongoing trade war with China heats up, it will likely move its import business from China to Vietnam.

“You really need a large center of mass lighting suppliers in one area to support lighting manufacturing,” he explains. “In large volume, really, China’s the only country in Asia that has that.”

Sometimes, however, being your own manufacturer can help you pivot any way the client wants. And if that client is an interior designer, that flexibility makes all the difference.

“Custom is well over 50 percent of our business,” Nancy Shott, Vice President of Marketing at Hammerton, says, “which means that most products we sell are customized to a client’s unique specifications.”

Based in Salt Lake City, UT, Hammerton offers customers two avenues of purchase: Hammerton Studio and Hammerton Signature. About 25 percent of Hammerton Studio orders involve custom, while nearly all products ordered through Hammerton Signature are customized. The custom products, usually for interior designers and their clients, often inform new product designs for the Hammerton Studio line.

“Because we do so much work directly with designers,” Shott says, “we have unique insight into where trends are headed in the industry.”

Take, for example, the Gem Collection for Hammerton Studio. The collection’s inspiration came from a custom project in which the interior designers wanted the glass to make a big statement. The designer had an art collector client in Colorado who wanted the lighting in the home to complement a 20-foot-tall Chihuly glass sculpture. The collector specified that the lighting could not be cookie-cutter and must be artwork unto itself.

The designer took the client’s specifications to Hammerton and worked with the company to create glass fixtures that wouldn’t get lost among the home’s artwork. One of the pieces of blown glass used in a fixture for the client’s kitchen became the inspiration for what was released in 2016, the Gem Collection.

Melting-Pot Pieces

Few lighting fixtures made here can truly call themselves 100-percent Made-in-the-USA — and that’s okay. Domestic manufacturers source raw materials in the U.S. and abroad to give customers the best quality, and the suppliers who make this happen have stories of their own.

Every day, Gand drives through Middlebury to get to work in Castleton, as do many of the designers at Hubbardton Forge, so when the Vermont Modern designers needed some help on the Copernicus Collection, the answer was right in front of them.

“Vermont Modern being a little bit more on the whimsical side,” Gand explains, “our designers were looking for components that were wooden spheres that we would drill holes in and isolate the wires that were bringing in the light.”

Someone in the factory knew someone at Maple Landmark, a Middlebury-based company that specializes in making eco-friendly wooden toys. The two companies connected, and now Maple Landmark supplies the maple wood for the Copernicus fixtures as well as the Plank LED linear pendant.

For almost 25 years, Justice Design Group has been getting the clay for its ceramic fixtures from the same supplier in California, and that relationship ensures the quality of its products. Levin says the clay supplier understands Justice’s unique needs and can help troubleshoot in the event that something goes wrong. When a large order comes through and requires more clay in a short amount of time, it pays to have a reliable friend in the company’s backyard.

In Utah, Hammerton’s relationship with a local supplier allows the company to offer the American Architectural Manufacturers Association’s 2604-certified finishes on their outdoor fixtures, as well as a lifetime limited warranty. Considering that outdoor lighting can fail in just one season, having fixtures that can stand up to the elements is a plus. Because of tthis certified finish, which protects the fixtures in harsh weather conditions, the company can stand by the warranty. “We’ve shipped thousands of fixtures since we started this process,” Shott says. “And we never see them again because they hold up beautifully in all climates.”

However, fixtures made with 100-percent-American parts rarely exist, and in some cases, they’re just not profitable. Components like knobs and wiring often come from China and South Korea, and metal wholesalers, the people who buy steel and aluminum and sell them to smaller companies like Hubbardton Forge and Hammerton, don’t disclose where their metals come from. For Hammerton, that’s not a problem.

“It doesn’t matter how you buy it,” Shott says. “Because of the nature of the industry, manufacturers have zero control of where it actually comes from, and to be quite candid, what we care about is quality, cost and reliable supply. You have to pick your battles.”

Metal wholesalers source from the U.S., Canada and other countries, and though they’ve gotten less press as of late than the Chinese tariffs, the steel and aluminum tariffs on Canadian steel continue to affect domestic manufacturing, as do the retaliatory tariffs on U.S. goods. At press time, the tariffs remain in place, and according to Bloomberg, U.S. lawmakers and the Canadian and Mexican governments want to remove the tariffs before ratifying the new U.S.-Mexico-Canada Agreement, the updated version of the North American Free Trade Agreement that President Trump signed back in November. Legislatures in all three countries must ratify the treaty, and there’s a chance Canada and Mexico may veto the new agreement if tariffs are not lifted. That puts U.S. manufacturers in a difficult position.

“We’re waiting to see what happens,” Gand says.

Family Affairs

In life, it is said that the whole is greater than the sum of its parts, but the welders, glass blowers and artisans who create these fixtures give each one its greatest value. In domestic manufacturing, it’s not uncommon to have family members working side by side. At Hammerton, a son brought his father on, and three sets of brothers work for the company.

Hubbardton Forge partners with local trade colleges to get young adults and even kids in middle school interested in learning a trade. Within the company now, a number of mother-daughter and father-son teams work in production. In fact, the man who perfected the company’s iconic steel leaves taught the craft to his son.

“It’s a craft that you teach someone else to do, that you share with someone else,” Gand says. “It’s skill and artistry; it’s something that has been learned over time.”

In the forge, training and development keep employees engaged, and as they work and move around, they become the company’s best form of quality control. At each step of production, the welders and artisans can take a product out of production if they feel it does not meet Hubbardton Forge’s standard. In fact, they’re encouraged to do so.

At Justice Design Group, each artisan contributes a creative talent, but they’re also responsible for keeping other aspects of production running smoothly. Electrical components and other similar materials in inventory can be monitored electronically, notifying the team when supplies are running low, but clay isn’t as easy to measure. The casters keep an eye on inventory, and the company relies on them to order more when needed.

“Our main caster has worked for us for almost 40 years,” Levin says. “He started in Justice Design in 1995, and he worked for my father and grandfather before that.” That caster’s daughter now works for the company in the finishings department. In addition, a 25-year veteran of the company has two sons and a daughter working there now, and the head of the molding department has a wife and daughter working at Justice Design as well.

Levin jokes that only about five families really work for the company. At the end of the day, the employees make the product American-made, and the traditions and their pride in their work shine the brightest light. “There’s no bigger compliment than when somebody asks if their child can join the company.”

Perfect Partnerships

Hubbardton Forge

The Copernicus Collection from Vermont Modern, Hubbardton Forge’s whimsical, eclectic line, uses maple wood from toy manufacturer Maple Landmark.

Justice Design Group

The clay for Justice Design Group’s ceramic designs has been coming from the same California-based clay supplier since 1995.

Hammerton

Because of its good relationship with a local supplier that makes the resistant finish on its outdoor lighting, Hammerton is able to offer its customers a limited lifetime guarantee on its outdoor fixtures.

What Constitutes Made in America?

The Federal Trade Commission (FTC) regulates the use of Made-in-America labels, and there are standards to be met if a company wants claim its products are truly made in the U.S. Here’s a quick look at what that means.

Made in America

- Products must meet the FTC’s “all or virtually all” standard to use the claim on products, labeling, advertising and other promotional materials. This also applies to using the claim in marketing, whether through digital or electronic mechanisms, such as internet or email.

- Claims can also be made through implication rather than directly stated — statements such as “true American quality” or iconography such as American flags or maps.

- Brand names or trademarks do not count as Made-in-America claims.

- If not all products in a line are made in the United States, companies cannot claim the whole line is Made-in-America.

- The FTC does not grant Made-in-America claims. Companies may use them so long as they are truthful and substantiated.

Assembled in America

- Products may be made from some imported components (a low percentage), but the bulk of the assembly is done in the U.S. Principal assembly must take place in the U.S. to use this claim.

- Substantial assembly goes beyond what the FTC calls “screwdriver assembly,” meaning the product must be significantly transformed.

- The parts used must not be pre-assembled themselves. For example, a computer made using imported parts (motherboard, components, etc.) cannot claim to be assembled in the U.S. because much of the building was done elsewhere. The assembly done in the U.S. is mostly putting the completed parts together.